COMBINING innovative vertical thermoforming technology and the special attributes of plastic, the Roll N Blow offers manufacturers an economical and simple way to produce bottles on-site.

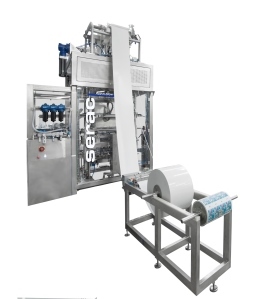

Drawing inspiration from the conventional flat thermoforming technology, the Roll N Blow machine from Serac uses ground-breaking tubular thermoforming technology to produce bottles from plastic reels. The vertical thermoforming process first forms the plastic sheet into a pipe before heating and blowing the bottle into a mold, producing bottles that appear no different to those made using blow molding.

A wide range of bottle designs can be produced using these machines which can form round shapes. This broadens options for manufacturers beyond large necks and small heights. In addition, compared with bottles produced using flat thermoforming, those made with the Roll N Blow machines demonstrate greater resistance to vertical compression.

The Roll N Blow uses tubular thermoforming technology to produce bottles from plastic reels. The process first forms the plastic sheet into a pipe before heating and blowing the bottle into a mold, producing bottles that appear no different to those made using blow molding

Smart technology suitable for PS and PP

Although originally designed to process polystyrene (PS), the Roll N Blow machines can now create bottles out of polypropylene (PP) reels. The equipment has been adapted to the specific properties of PP, which means manufacturing bottles out of this material will require only a proper specification of the plastic sheet, thereby offering a simple and practical solution for delivering new bottle types and designs.

Already, four companies in North Africa and Europe use the technology for PS and PP bottles for the packaging of drinking (or drinkable) yoghurt.

Serac has recently sold two new Roll N Blow machines in Europe for on-site manufacturing of dairy drinks bottles out of PP reels. This further confirms the benefits and reliability of the vertical thermoforming technology and reflects market interest in on-site PP bottle production.

Using the Roll N Blow technology in association with PP as a base material offers a wider range of possibilities for packaging innovation. Compared with PS, PP provides a better barrier against moisture and withstands higher temperatures. It is also more flexible and shock resistant. Further, PP shows a better chemical stability than PS.

All these properties make PP a more suitable material for a broader variety of products than PS. The latter is mostly used for chilled products with a short shelf life such as pasteurized milks, drinking yoghurts, and probiotics.

Cost-effective technology for new designs, new markets

With its capability to work with either PS or PP, the Roll N Blow machines are providing manufacturers with an affordable and secured technology to produce white, colored, printed, opaque, or translucent bottles. Manufacturers can also use the technology to design bottles with up to 190mm in height as well as bottles with a blown neck, a reduced calibrated neck, or fitting standard cap dimensions. These can be hot or cold filled, and sealed with an aluminum foil, or plastic cap.

Designs from the Roll N Blow include up to 190mm high bottles, bottles with a blown neck, a reduced calibrated neck, or fitting standard cap dimensions

The Roll N Blow technology likewise offers manufactures the window to try producing squeezable bottles that can be emptied to the last drop or dispense high viscous products. As PP bottles can be microwavable, bottles for convenience liquid food could not be too remote an idea for product development. Another future development could be PP bottles with barrier such as EVOH to provide an oxygen barrier to containers of liquid food products such as sauces, baby food, and soups.

By adapting the Roll N Blow Technology to PP processing, Serac offers manufacturers, in particular those from the dairy and food industry, broader opportunities to gain a foothold in the developing single-serve market. On-site thermoforming of bottles using PP reels can help companies enter new market segments at controlled costs. These new sectors include ESL dairy drinks and nonrefrigerated drinks such as sterilized milks and UHT flavored milk drinks.

The Roll N Blow machine is very simple to operate, making it an ideal solution for companies without experience in bottle manufacturing. It uses processes that are very similar to the manufacturing of pouches from plastic foils or carton packages from carton reels. The technology does not require melting of the plastic, which means very little expertise in plastic processing is required.

The machine can be easily started and shut down to suit filling requirements. The use of plastic sheets ensures a uniform distribution of the material without having to monitor advanced parameters in the heating and blowing process.

All these provide a practical and secure option for dairy and food companies willing to diversify their product portfolio and upgrade their product offerings with small bottle packaging.

Moreover, technology provides a cost-effective solution from investment to day-to-day operations.

The vertical thermoforming process reduces the footprint of the packaging production unit. As the machines are designed to serve as a streamlined solution for on-site bottle manufacturing, they require less equipment than a conventional molding unit. With the bottle going straight from the machine to the filler, manufacturers eliminate the need for storage tanks and unscramblers. And because the Roll N Blow can process preprinted plastic sheets, even sleeve applicators are no longer necessary.

Further, significant savings along the supply process—from manufacturing to transport and storage—can be achieved because bottles can be produced from material in reels. In addition, the machines consume far less energy than other blowing systems with bottles blown at a low pressure of less than 6 bars and at low temperature below 150°C.

Yeezy Wave Runner 500

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login