Thermoforming machines geared to provide special packaging products with the necessary features are bringing enhanced efficiency and flexibility. The machines come with more than simple solutions as they also enable manufacturers to meet various hygiene regulations.

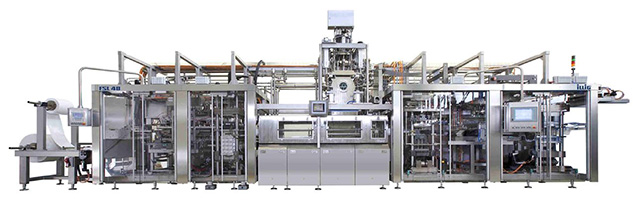

The newly designed FSL 48 form, fill and seal line, tailored to meet the demands of the food industry, and especially the dairy industry, was the core element of ILLIG's trade fair appearance at Interpack 2014 in Düsseldorf. An in-mould labeling (IML) station is integrated in the FFS line and employed to decorate the sales packs in a brilliant way, directly in the thermoforming process. Most conventional cup geometries which can be produced on form, fill and seal lines can be realised.

By employing the newly designed filler, suitable for CIP (Cleaning in Place) and SIP (Sterilisation in Place), the FSL 48 can be equipped to meet a variety of different hygiene demands by the food industry, through to hygiene class IV according to VDMA (hygienic filling machines). The thermoformer's format area, 480 mm x 320 mm, is designed in such a way that after filling, sealing and punching always a complete cycle output, e.g. 12 standard curd packs, can be placed in a box, adjusted in size to a pallet. The layout of the format area can be adjusted to enable production of single or double cups, 4-up or 6-up trays. A working speed of up to 30 cycles per minute is achieved.

Strong emphasis on flexibility

By employing the new multi-lane filler dairy products of different flavours can be filled in packs, labeled accordingly, in one machine format by the FSL 48. The line presented at the Interpack trade fair filled four different flavours at the same time using a 12-up layout. Subject to the format layout of the ILLIG FSL 48, packs containing up to six different flavors can be produced at the same time and packed directly in a crate suitable for the supermarket shelf - manual sorting is no longer required.

The controlled motion sequencing of the line, which is completely servo driven, results in very smooth running. This means that even very liquid products can be packed and there is no product spilling on the sealing rims. All conventional materials suitable for processing on FFS lines can be processed on the new FSL 48, such as PS, PP, multilayer materials (e.g. PS/EVOH/PE), APET and even foils made of PLA biopolymer (polylactic acid). The hygiene levels of the machine reach from forming with sterile air and complete covering of the filling range (also available in CIP/SIP version) through to sterilisation of the lid material by UV radiation or complete aseptic unit in the area of the filling tunnel.

The IML unit integrated in the forming station of the FSL 48 works with printed label blanks from the magazine. Numerous decoration options can thus be achieved in a simple way: One-sided, two-sided, three-sided (e.g. U-shaped), four-sided or even five-sided (including bottom decoration e.g. with integrated barcode). A great variety of cup shapes can be smoothly decorated with attractive labels in photo quality since for IML walls to be decorated don't have to be vertical.

Inserting of labels in the mould is an additional work step in the thermoforming process. This step is performed parallel to the ongoing forming process in the FSL 48 so high productivity (cycle speeds) is still achieved. The lower mould part is designed as a cube which turns by 90 degrees with each cycle. The labels are always inserted and fixed in the cavities in the position before swiveling to the forming position.

In terms of costs, IML thermoforming developed by ILLIG is more favourable than e.g. IML injection moulding which is also used for decoration of plastic packs. On one hand, investment costs for moulds and maintenance costs are lower than in injection moulding. On the other hand, thermoformed articles can be manufactured with thinner walls and are thus lighter than injection moulded articles. And furthermore less energy is required for processing in addition to the considerably lower material consumption. IML thermoforming provides economic benefits in particular because multi-cavity moulds can be employed.

Packaging economically

MULTIVAC has launched its R 900 machine, the latest model of its thermoforming packaging machines, which is particularly suited to large products requiring an extremely deep pack cavity. The R 900 was developed as part of a customer project with a manufacturer of medical products, who packs multi-component systems for the operating theatre on it.

The OP sets, which are packed on the new R 900 from MULTIVAC, consist of ready-to-use components such as syringes, scalpels, clamps, suture material etc, which are put together based on the individual surgical requirements. These multi-component systems are first packed in a plastic box or a flexible pack, and then wrapped in sterile OP drapes.

"So that the complete set, which is up to 15 centimetres high and often consists of 2 or 3 layers, can be packed automatically on a high-output thermoforming packaging machine, we have developed a new machine concept, which enables a thermoforming depth of 450 mm to be achieved. The machine frame height is consequently 1300 millimetres. With the first customer machine it is therefore possible to form and seal large packs in a width range of 200 to 600 millimetres, up to 430 millimetres in length and up to 450 millimetres in depth", says Natalie Schmid, Product Manager at MULTIVAC.

The use of the thermoforming packaging machine, which was developed in close cooperation with the user, brings significant benefits to this supplier of medical technology. The products were previously packed in special film pouches. This meant that there were frequently faults in the packs, since creases formed in the pouch neck during sealing. Thanks to the new thermoforming technology, the number of faulty packs can now be reduced. The loading of the products into the pack can also now be automated. The products are loaded into the pack cavities with several robots.

Flexible films (mono PE) with a thickness of approx. 600μ are used for the packaging films. A thermoforming ratio of up to 14 can be achieved with the new machine design. The R 900 is equipped with a jumbo film unwind. MULTIVAC has integrated a separate film unwind and a separate pre-sealing station in the packaging machine for the Tyvek® strip, through which the OP kit is subsequently sterilised.

The forming station of the R 900 is equipped with a new lifting unit with servo drive, and also with a trapezoidal spindle for the forming plug, which optimises the forming of the pack cavities. The system for explosive forming has also been adapted, in order to be able to provide the large volumes of air required for the big pack cavity.

The sealing die and cutting unit of the R 900 also has new servo lifting units, which are particularly energy-efficient and which generate a closing force of three tonnes. MULTIVAC has also integrated a new common air discharge for the forming system.

The support system with roller conveyor and discharge conveyor can be adjusted in height by means of servo motors. The type of QRP cross cutter developed for special materials has been integrated in the machine.

Due to the machine height of 1.30 metres, MULTIVAC has equipped the machine with a special lifting trolley of the HW 201 type. The doors in the area of the lifting units can also be opened more easily thanks to a special type of side panel. In addition to this, a special safety concept has been developed with sliding guards at hazard points in the loading area and outfeed.

Air Jordan IV 4 Running Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login