THE GLOBAL snack market is currently valued at around US$100bn1 and this is only set to grow as manufacturers expand their product offering to meet demand for new tastes and varieties. With huge sales potential, it is more important than ever for snack manufacturers to improve their process efficiency and increase high quality output to remain competitive. However, it can be challenging for plant managers to achieve this when working with several equipment suppliers, as this often leads to inefficient operations and incompatible components. In this report, Chris Jones, Group Sales Manager – Controls for tna, explores the benefits that a total systems approach can bring to snack manufacturing and how it can be used to overcome these difficulties.

Chris Jones, Group Sales Manager – Controls for tna

Then and now

The traditional snack manufacturing line is improving all the time, however there are some basic elements that form an integral part of the setup. It usually comprises an area for spraying and seasoning, along with metal detection and verification solutions for product safety. In addition, there are also numerous conveyors to transfer products along the line, weighers to ensure accurate quantities, and packaging equipment to prepare the product for end-user consumption. In the past, snack manufacturers used to install the components of the packaging line from different suppliers, looking for the specialist in each area. However, more and more plant managers are now looking for a partnership with packaging machinery providers and specifying total systems from start to finish. These partner suppliers can tailor the solutions to the individual plant needs, taking into consideration the environment, snacks processed and future growth plans to overcome any restrictions or maximise the available resources and plant footprint.

Conveying system

Complete control

As production lines become more complex, and output targets increase, more and more components need to be integrated into the same network. Even when all machines are supplied from the same equipment manufacturer, there is a risk of interrupted product flow if each section operates in isolation without communicating with the rest of the line. In this case, automation can be considered the ‘glue’ that holds an efficient snack manufacturing line together. An effective control system is key to ensuring that the snack line remains simple to use and that movement between each area of the production line is seamless. These systems can put an end to isolated areas of control, which impede smooth product flow and can lead to inefficient operations.

Products are now processed at unprecedented speeds, and just a single fault in one area of the line can affect the entire production cycle, leading to a large quantity of rejected products, unnecessary downtime and excessive waste. With a properly designed control or recipe system, it is possible to control the entire production line from a single point. This improves efficiency and reduces changeover time as product selections need only be made once, vastly limiting the risk of human error.

Good control systems should also gather information from the entire line and store it in a central database, allowing plant managers to filter the data and create configurable reports to demonstrate trends and increase control over the process. Known as a Human Machine Interface (HMI), this machine provides status and production data, enabling operators to monitor any unusual activities and react quickly and efficiently should an incident occur, and ensure that production is not affected. Not only does this speed up production, but it also creates a greater level of transparency and accountability within the snack manufacturing process.

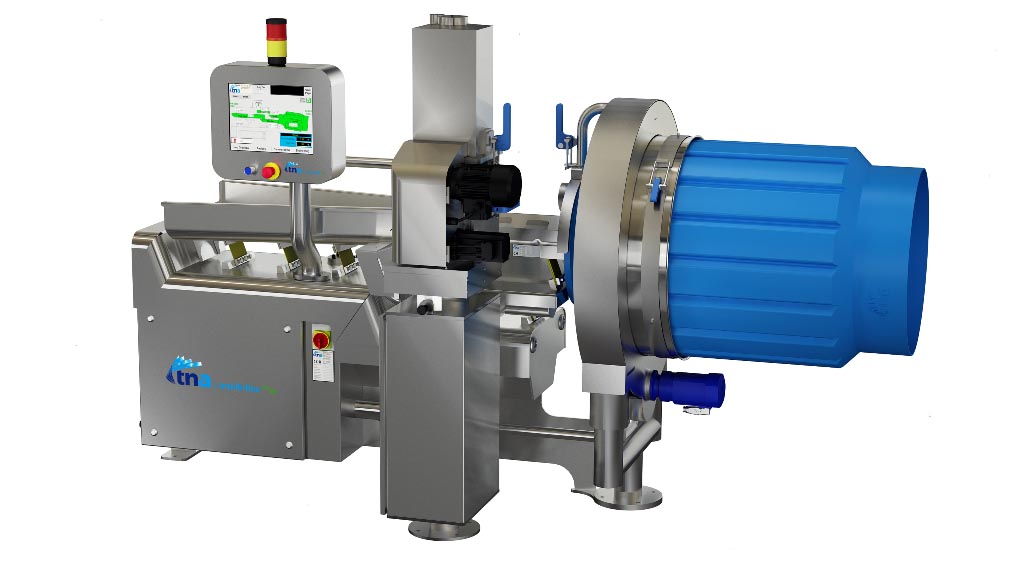

The tna intelli-flavOMS 5 on-machine seasoning system offers powder flavouring and liquid oil in one drum

Top traceability

As the latest news headlines and the number of product recalls demonstrate, traceability is an essential element of all food manufacturing. Consumers are increasingly scrutinising food labels to find out where their products come from, and snacks are no exception. Recognising this, governments around the world have sought to implement new regulations to address food safety and avoid future product recalls. In the US, the FDA introduced the FSMA in 2011, which spans from the source to the processing and through the packaging stage. It is designed to establish a risk-based and global systems approach to food safety. In the EU, the General Food Law enforces similar requirements, and is set to be supplemented in December 2014 by the EU Food Information for Consumers Regulation 1169/20112. It is therefore important for manufacturers to have tight control over their products, and clearly label what exactly is within the packaging to comply with regulation and ensure the safety of the consumer, as well as protecting their brand integrity.

Food safety can be assured by improving traceability and in-line checking throughout the entire process, facilitated by the adoption of a fully integrated control system. Data collection equipment, such as barcode scanning systems, can accurately verify that the correct batch is being processed by scanning the product barcode and cross-checking it with the available data. Date code assurance systems ensure that the date code is printed, complete and legible, whilst in-line monitoring systems, such as metal detection, will ensure the absence of foreign bodies within the product prior to packaging. By integrating these systems into the total snack production line, it is possible to achieve a rigorous system of product traceability.

Heavy-coated products don’t lose flavour when they pass through the roflo horizontal motion distribution system since the seasonings don’t stick to the pans

The entire package

A potential issue that can occur when installing machinery from different suppliers is that the elements cannot keep pace with each other. For example, if a conveying system limits throughput to only 100bpm, whilst the packaging system can handle 250bpm, it leads to lost productivity. It is possible to achieve greater efficiencies when working with a single provider of snack manufacturing solutions, as all elements are likely to be working to the same speeds to achieve higher levels of product throughput.

When reaching high speeds, however, it is essential to maintain high quality. Appealing packaging can be a key way for manufacturers to stand out on increasingly crowded shelves, so it is essential that the product looks good, and that the snack inside is intact to meet consumer expectations. Faster throughputs should have no impact on product quality or cause increased waste during processing; product integrity should be maintained throughout the line. It is therefore imperative that any snack line comprises equipment which is designed to prevent product damage. In addition, manufacturers using equipment from a single manufacturer can standardise output in order to maintain high quality as each element works to the same configuration every time.

Working with a single equipment supplier can also be extremely beneficial if a comprehensive after sales service is available. The training of operators for all line components can be carried out simultaneously, and full support throughout the life of the line. It is also vital to ensure the supplier has local sourcing of all spare parts to maintain the productivity of a snack line. Downtime can be extremely costly, and by working with a single partner, lengthy stops can be minimised and maintenance efficiency improved.

Whilst in the past many snack manufacturers may have incorporated a variety of different suppliers’ equipment into their production line, more and more are seeking total solutions. With a line that is tailored to each plant’s needs, using the total systems approach key productivity objectives can be met, efficiency can be improved and throughput increased, allowing manufacturers to make the most of the growing snack market.

References:

1Innova Market Insights 2013

2 http://ec.europa.eu/food/food/labellingnutrition/foodlabelling/proposed_legislation_en.htm

Zoom Lebron XI 11

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login