FachPack 2015 coversnew developments expected to shape the future of packaging in different sectors.

One is the convenience trend which is shaping developments in the foodstuff packaging sector, with stand-up sachets increasing in popularity and squeeze bags widely adopted for on-the-go baby food such as fruit pulp, yoghurt specialties, and vegetable puree. Screw-on feed spoons are available from online shops, with screw-tops serving as an adapter. Dry and powder products in flat, square sachets are being replaced by bags of sauces and instant soups that require only reheating.

Product individualization is another key trend, providing consumers flexibility in meeting preferred variations in product mixes. These raise the need for innovative labeling technologies and solutions as many variations of consumers’ required product combinations need to be produced and packed while retaining the individual details and information in the labels.

For labeling and marking solutions, clear product identification becomes an even more important field as cases of brand fakes, particularly in the health and beauty industry, increase due to online shopping. Fakes are becoming increasingly professional. Pharmaceuticals packaging standardized serialization is placing new requirements on the handling of growing data volumes, with all product and logistics information for each individual pharmaceuticals packaging requiring registration and storage. Intelligent software architecture, which can be combined with modern machine and printing technology, can support individualization and track & trace systems for efficient, full-coverage product tracking and secure product authentication and reliable protection against falsification.

For the packaging machine manufacturers, the diversity of product variations posits the challenge of ensuring machinery and facilities not only fill products in equally sized packs but also completely control various packaging sizes and styles. They need to know the importance of machine design, with the individual components optimally coordinated with each other and replaced quickly if required, to achieve an efficient and flexible fully automatic packaging system. Tray-sealers must be capable of processing all the tray formats and materials within the product size. The cover film or protective glass should also be flexible. Operators should be able to make adjustments and product changes quickly, even without tools through quick-release caps and fasteners. These underscore the importance of modular designs, which allow various functional modules to be made in the same machine housing and setup area. Such designs allow machines to be used more quickly and upgraded or retrofitted more easily for future needs.

Some products featured at the show:

Meypack unveils new case packer

DESIGNED to end-package folding boxes containing pouches of milk powder into trays with or without lids and wrap-around cases, the VP 453 is equipped with a Siemens Simatic S7-1500 control system and an expanded machine analysis through the new Simatic HMI Comfort Panel TP1500. An integrated, energy-saving SEW Moviaxis-Servosystem boosts machine dynamic.

The VP 453 is capable of processing eight different formats, with additional formats possible for support later. It uses a single track paddle chain to set the folding boxes, which enter the machine lying down, upright. Folding boxes of varying thickness can be processed gently through adjustments on the paddles of the paddle chain.

The case packer has an open construction that allows easy cleaning and maintenance. The bearings, chains, and linear bearings are lifetime lubricated, and cable management, including pneumatics, conforms to high industrial standards. The integrated Nordson hotmelt ProBlue Liberty tank less technology extends storage capabilities.

UltraClear PP packaging, other solutions from Milliken

Milliken highlighted its alternative to glass clear packaging, the UltraClear PP. Now with the Millad NX 8000 series, the UltraClear PP combines exceptional aesthetics and lowest weight potential. The clarity boost provided by Millad NX 8000 addresses the milky appearance of PP in thermoforming to yield a highly attractive transparency similar to PET for sheet and thermoformed applications such as meat trays, clamshell containers, and lids.

The UltraClear PP provides the performance benefits of mono-material packaging, is easy seal, and is chemical, impact and heat resistant. Microwaveability and hot-fill capability are also features that expand application possibilities.

Statistics show the product’s productivity improvements, energy savings, low carbon footprint, and cost-efficiency compared with alternative plastics. Up to 70 trays from 1kg of PP can be produced as opposed to 57 trays from PET of the same weight.

For PET packaging applications, Milliken’s ClearShield Colorless UV Absorbers extend the shelf life of packaged materials and protects brand image for food, beverages, and consumer products, offering a new UV protection performance standard for PET.

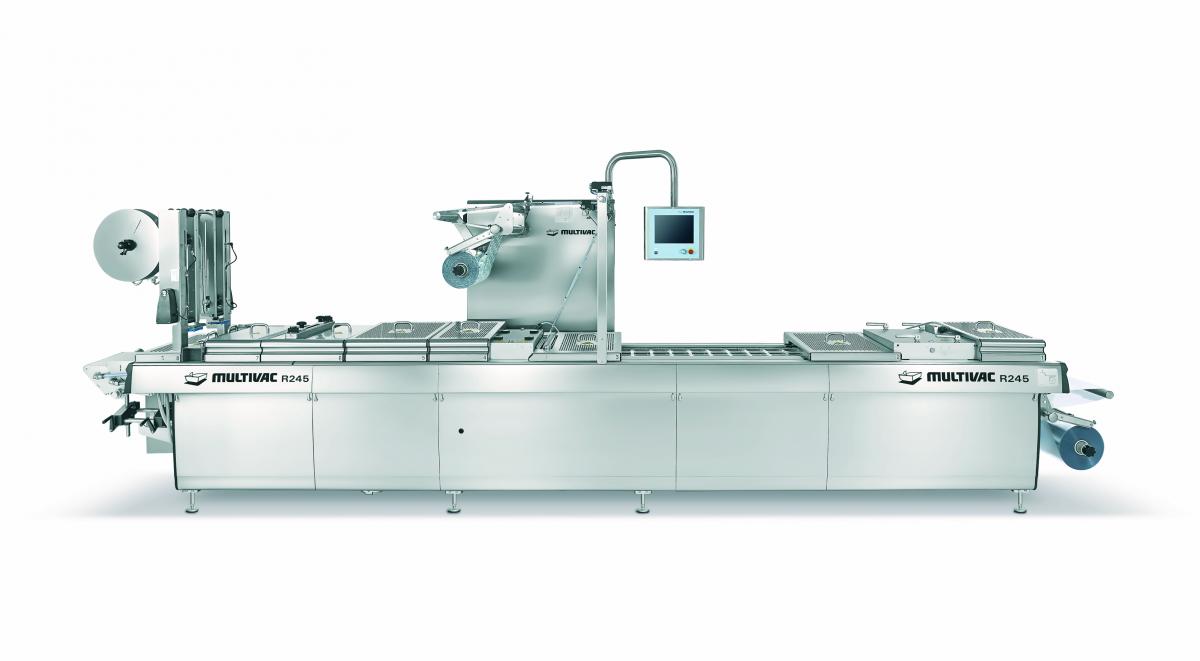

Solutions from Multivac

The R 105 MF thermoforming packaging machine from Multivac is an entry-level model for producing MultiFresh vacuum skin packs. The portfolio includes a wide range of skin films for MultiFresh applications.

Multivac presented approaches to improve energy, material, and process efficiency using the R 245 thermoforming packaging machine, which adopts innovative die technology to cut consumption of packaging materials. The machine incorporates an MR293TT direct web printer and two MR625 OP cross web labelers for marking and labeling the packs. The I 211 checkweigher checks the weight of the packs, while the integrated MBS 100 belt system converges the packs, and the MPS 302 pack stacker handles stacking.

The T 800 high-output traysealer features an additional automatic tray denester with a tracking unit. The trays are labeled by a L 310 conveyor belt labeller. The packaging line has an I 310 metal detector for quality inspection.

FachPack 2016 will be held from 27-29 September in Nuremberg, Germany.

Crazy Explosive Boost 2017 PK Low

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login