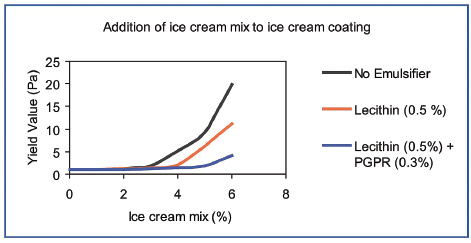

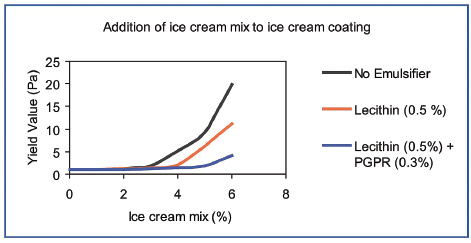

FOR the ice cream industry, chocolate and compound coatings are widely used to add extra value to the ready-to-eat products. Yet in many ways, chocolate is by nature incompatible with the ice cream and this can create problems at the production stage. In manufacturing chocolate it is a general rule to avoid water during the entire process, and in the conching step a lot of effort is exercised to reduce the total water content in the chocolate well below 1 per cent. Higher content of water will increase the viscosity of the chocolate dramatically making it unsuitable for production, as the flow properties will become too poor. On the other hand, ice cream is a system typically holds 65% water, a great proportion of which will be found in a liquid stage during the manufacturing process. Whereas the temperature is kept as low as possible during manufacturing of ice cream, the chocolate has to be heated to 30° to 40°C in order to remain liquid. The contact between the frozen surfaces of the ice cream sticks and the warm chocolate will thaw some water which will migrate into the chocolate causing an increase in viscosity and yield value resulting in increased layer thickness and crystallisation time. Emulsifiers like lecithin but especially PGPR (polyglycerol polyricinoleate) are known to improve the flow properties of the liquid chocolate mass and to a certain extent, to counteract this negative effect of water. It is therefore interesting for the ice cream industry to take food emulsifiers into consideration when working with liquid chocolate or ice cream coatings.

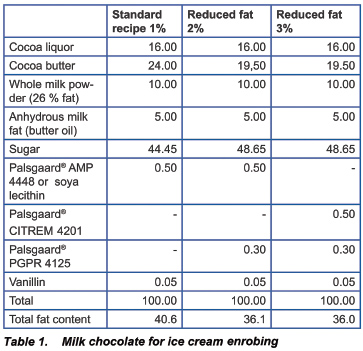

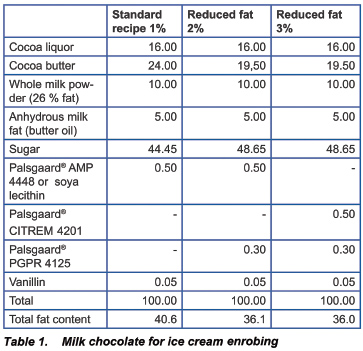

Chocolate for icecre am - typical enrobing In many countries, certain purity standards must be followed for chocolate. There are restrictions on the minimum content of cocoa components and on the type of fats allowed. Also the use of food emulsifiers is restricted and regulated according to local food standards and legislation. Typically the total fat content of an ice cream chocolate will reach approx 40 to 45 per cent. In terms of fat, cocoa butter is the main component in chocolate but the addition of milk fat makes chocolate softer, more plastic in consistency and shows less contraction during crystallisation. Even in dark chocolate for ice cream applications it is highly recommended to add 4 to 5 per cent anhydrous milk fat. This will reduce the cracking problems, especially in extruded ice cream types where the centre is hard and there is no room for this contraction, and hence the chocolate will crack. Many countries also allow addition of up to 5% cocoa butter equivalents that help plasticise the chocolate.

Ice cream coating - compound coating Ice cream coatings - typically thin layers are manufactured from rather inexpensive fats like coconut oil or hydrogenated palm kernel fat. Contrary to an ice cream stick covered with a thick layer of real chocolate, the ice cream coating should only form a thin layer round the ice cream stick. The total fat content is therefore often above 60% in order to achieve a sufficient thin layer and a short crystallisation time. To "soften" the fat phase, approx 8% liquid oil will provide the necessary plasticity to the coating. Addition of approx 5% skimmed milk powder to a dark coating will improve the flavour of the coating balancing the bitterness of the alkalised cocoa powder. Emulsifiers Emulsifiers work in the chocolate by improving the flow properties of the liquid chocolate mass. Some emulsifiers lower the plastic viscosity whereas other emulsifiers influence the so-called yield value. The yield value can be defined as the energy input needed to initiate flow of the chocolate. As an added benefit for the ice cream manufactures, the emulsifiers also have the ability to absorb a limited amount of water transfer

Nike Air Max FOR the ice cream industry, chocolate and compound coatings are widely used to add extra value to the ready-to-eat products. Yet in many ways, chocolate is by nature incompatible with the ice cream and this can create problems at the production stage. In manufacturing chocolate it is a general rule to avoid water during the entire process, and in the conching step a lot of effort is exercised to reduce the total water content in the chocolate well below 1 per cent. Higher content of water will increase the viscosity of the chocolate dramatically making it unsuitable for production, as the flow properties will become too poor. On the other hand, ice cream is a system typically holds 65% water, a great proportion of which will be found in a liquid stage during the manufacturing process. Whereas the temperature is kept as low as possible during manufacturing of ice cream, the chocolate has to be heated to 30° to 40°C in order to remain liquid. The contact between the frozen surfaces of the ice cream sticks and the warm chocolate will thaw some water which will migrate into the chocolate causing an increase in viscosity and yield value resulting in increased layer thickness and crystallisation time. Emulsifiers like lecithin but especially PGPR (polyglycerol polyricinoleate) are known to improve the flow properties of the liquid chocolate mass and to a certain extent, to counteract this negative effect of water. It is therefore interesting for the ice cream industry to take food emulsifiers into consideration when working with liquid chocolate or ice cream coatings.

FOR the ice cream industry, chocolate and compound coatings are widely used to add extra value to the ready-to-eat products. Yet in many ways, chocolate is by nature incompatible with the ice cream and this can create problems at the production stage. In manufacturing chocolate it is a general rule to avoid water during the entire process, and in the conching step a lot of effort is exercised to reduce the total water content in the chocolate well below 1 per cent. Higher content of water will increase the viscosity of the chocolate dramatically making it unsuitable for production, as the flow properties will become too poor. On the other hand, ice cream is a system typically holds 65% water, a great proportion of which will be found in a liquid stage during the manufacturing process. Whereas the temperature is kept as low as possible during manufacturing of ice cream, the chocolate has to be heated to 30° to 40°C in order to remain liquid. The contact between the frozen surfaces of the ice cream sticks and the warm chocolate will thaw some water which will migrate into the chocolate causing an increase in viscosity and yield value resulting in increased layer thickness and crystallisation time. Emulsifiers like lecithin but especially PGPR (polyglycerol polyricinoleate) are known to improve the flow properties of the liquid chocolate mass and to a certain extent, to counteract this negative effect of water. It is therefore interesting for the ice cream industry to take food emulsifiers into consideration when working with liquid chocolate or ice cream coatings.  Chocolate for icecre am - typical enrobing In many countries, certain purity standards must be followed for chocolate. There are restrictions on the minimum content of cocoa components and on the type of fats allowed. Also the use of food emulsifiers is restricted and regulated according to local food standards and legislation. Typically the total fat content of an ice cream chocolate will reach approx 40 to 45 per cent. In terms of fat, cocoa butter is the main component in chocolate but the addition of milk fat makes chocolate softer, more plastic in consistency and shows less contraction during crystallisation. Even in dark chocolate for ice cream applications it is highly recommended to add 4 to 5 per cent anhydrous milk fat. This will reduce the cracking problems, especially in extruded ice cream types where the centre is hard and there is no room for this contraction, and hence the chocolate will crack. Many countries also allow addition of up to 5% cocoa butter equivalents that help plasticise the chocolate.

Chocolate for icecre am - typical enrobing In many countries, certain purity standards must be followed for chocolate. There are restrictions on the minimum content of cocoa components and on the type of fats allowed. Also the use of food emulsifiers is restricted and regulated according to local food standards and legislation. Typically the total fat content of an ice cream chocolate will reach approx 40 to 45 per cent. In terms of fat, cocoa butter is the main component in chocolate but the addition of milk fat makes chocolate softer, more plastic in consistency and shows less contraction during crystallisation. Even in dark chocolate for ice cream applications it is highly recommended to add 4 to 5 per cent anhydrous milk fat. This will reduce the cracking problems, especially in extruded ice cream types where the centre is hard and there is no room for this contraction, and hence the chocolate will crack. Many countries also allow addition of up to 5% cocoa butter equivalents that help plasticise the chocolate.  Ice cream coating - compound coating Ice cream coatings - typically thin layers are manufactured from rather inexpensive fats like coconut oil or hydrogenated palm kernel fat. Contrary to an ice cream stick covered with a thick layer of real chocolate, the ice cream coating should only form a thin layer round the ice cream stick. The total fat content is therefore often above 60% in order to achieve a sufficient thin layer and a short crystallisation time. To "soften" the fat phase, approx 8% liquid oil will provide the necessary plasticity to the coating. Addition of approx 5% skimmed milk powder to a dark coating will improve the flavour of the coating balancing the bitterness of the alkalised cocoa powder. Emulsifiers Emulsifiers work in the chocolate by improving the flow properties of the liquid chocolate mass. Some emulsifiers lower the plastic viscosity whereas other emulsifiers influence the so-called yield value. The yield value can be defined as the energy input needed to initiate flow of the chocolate. As an added benefit for the ice cream manufactures, the emulsifiers also have the ability to absorb a limited amount of water transferNike Air Max

Ice cream coating - compound coating Ice cream coatings - typically thin layers are manufactured from rather inexpensive fats like coconut oil or hydrogenated palm kernel fat. Contrary to an ice cream stick covered with a thick layer of real chocolate, the ice cream coating should only form a thin layer round the ice cream stick. The total fat content is therefore often above 60% in order to achieve a sufficient thin layer and a short crystallisation time. To "soften" the fat phase, approx 8% liquid oil will provide the necessary plasticity to the coating. Addition of approx 5% skimmed milk powder to a dark coating will improve the flavour of the coating balancing the bitterness of the alkalised cocoa powder. Emulsifiers Emulsifiers work in the chocolate by improving the flow properties of the liquid chocolate mass. Some emulsifiers lower the plastic viscosity whereas other emulsifiers influence the so-called yield value. The yield value can be defined as the energy input needed to initiate flow of the chocolate. As an added benefit for the ice cream manufactures, the emulsifiers also have the ability to absorb a limited amount of water transferNike Air Max

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login