Tool Center Point Management (TCPM) - or Rotary Tool Center Point Control (RTCPC) as it is sometimes referred to – is a feature within advanced machine tool controls that significantly simplifies the complexity of 5-axis programming and setup. If we try to visualise exactly what is happening as a tool moves around the part in 5-axis simultaneous machining, and try to imagine the types of calculations that are necessary to keep everything under control during this fluid dance of the tool-tip, it doesn't take long to realise that there is much more going on behind the scenes than what first meets the eye.

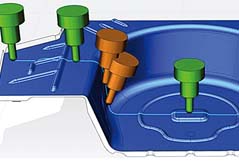

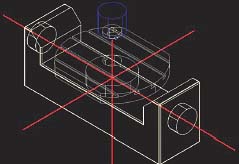

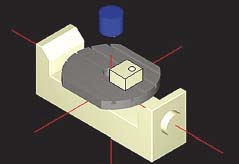

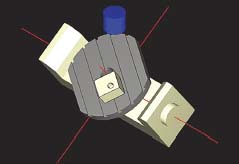

All 5-axis machines, regardless of the actual axis configuration, have a fixed mechanical centerline for the rotary or tilting axes of the machine, around which each particular axis rotates (see Fig. 2). The surface of the machine table, the position of the workpiece, the spindle gage line, and the tip of the cutting tools are all located some measurable distance away from these centerlines (see Fig. 3). When we perform the physical part and tool setup of the machine, there has to be something to account for and track all of these varying distances as the part is machined, and as the tool and the workpiece move throughout machine space (see Fig. 4).

Figure 2

Figure 2

Figure 3

Figure 3

Figure 4

Figure 4

Before TCPM was available, the necessary tracking was accounted for within the program itself, which proved to be problematic and time consuming to say the least.

When programming a part without TCPM, the programmer had to program everything from the centerline of rotation instead of the traditional workpiece zero point. This meant that the solid model had to be moved away from the zero reference point in the CAM system, the exact same distance as it was physically on the machine tool. The program had to be created with the use of the postprocessor, and then tested on the machine. If any positional adjustments had to be made: the solid model had to be repositioned in CAM space, the program would be reposted, and the entire process would be repeated as many times as necessary. After a considerable amount of preparation, reposting of the program, and a few dry-runs of trial and error, the program would be ready to run successfully and the job could be completed. However, even after all of this preparation was complete, once the workpiece was removed from the machine, all of the above steps would be necessary to complete the part again in the future. This meant that every time a repeat job was set up, this tedious process was necessary to complete the job. The entire process just wasn't efficient.

Machine tool companies began to realise the machine control itself needed to accommodate for all of the kinematics and movements of the machine, and automatically control the correlation between all of the necessary data points: machine centerline, spindle gage line, tool tip, and the workpiece zero point. There needed to be something that would make the use and implementation of 5-axis technology easier and more efficient in order for it to become more widely used.

Since TCPM was introduced, the entire process has not only become more controlled, but the entire setup procedure has been simplified. The program can now be posted with all program reference data originating from the actual workpiece coordinate system, and not from the rotary or tilting axis centerlines. This means the part setup and part programs are both independent from the machine setup, and the part setup can be performed in the same simple manner as it would be on a 3-axis machine—just locate the corner of the workpiece with an edgefinder. All of this proves to make the whole theatrical performance of the old technology non-existent. Instead, the whole process is more efficient, quicker, and much, much, easier for the programmer and the machine operator to complete.

UltiMotion

UltiMotion is simply software that controls the motion of each of the machine axes independently. The feature takes the hardware out of the process of controlling the motion of the machine axes, and allows the CNC control the ability to react smoother and quicker to variations in the movement of the machine. Rather than a "closed loop" system – where the axis reports its location to the motion control board (via the motor encoder) - UltiMotion is an "open loop" system: where the software continuously monitors the actual location of all axes individually, and adjusts the voltage and velocity to the motor (to speed it up or slow it down as necessary) in real-time - to be sure that all axes reach their programmed positions at the same time. This continuous "real-time" monitoring of the axes is what gives us the smoother and faster motion of the machine, therefore providing a better surface finish in a shorter cycle time.

Let's look at a short analogy that I like to use when explaining UltiMotion. In this analogy, UltiMotion becomes a Project Manager for a very large project (overall part program), and is in charge of five subordinate employees (individual machine axes), each of whom has a separate task to perform that will ultimately impact the completion of the overall project - which is to insure that all five machine axes arrive at their programmed positions at the same time. To complete this project successfully, the Project Manager must break each task of the project (individual lines of G-code in the program) into smaller tasks that can be assigned to each of the five subordinates…the X-axis, the Y-axis, Z-axis, spindle, tilting axis, and rotary axis servo drives.

The commands will be assigned to the subordinates as necessary, and monitored in real-time as they are executed. If one or more of the axes begin to fall behind, or move ahead of the rest of the group, then the Project Manager will issue corrective action (increase or decrease voltage to the corresponding axis) to correct the unwanted behaviour. This will continue, with each of the five subordinates, until the project task has been completed, and all five axes have arrived at the programmed location successfully. Then the next command will be executed in the same manner until the entire machine program has been completed.

The ability for the control to monitor axis movements, and to make real-time corrections as necessary, is the secret sauce that makes UltiMotion work so well. In the traditional "closed-loop" scenario, the CNC control must wait for the encoder position to be reported via the motion control hardware, and the corrections cannot happen as quickly or as smoothly as they do with UltiMotion's software controls.

Alle Artikel

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login