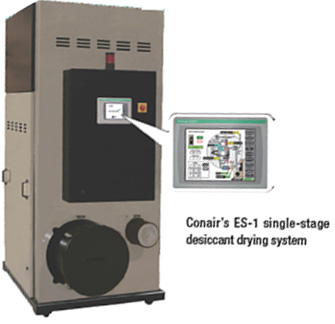

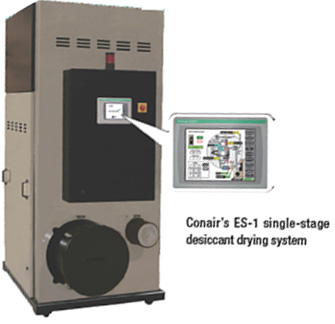

More advanced auxiliary equipment are helping processors improve the efficiency of their production. New cooling/ drying equipment and blenders/mixers are responding to the market's demand for energy saving, efficiency and improved quality of finished products. Conair recently expanded its drying product line to include the new ES-1 single-stage desiccant drying system that offers advanced control and energy-saving features. The EnergySmart™ Single-Stage ES-1 system was developed for processors of PET and other polymers that require high drying temperatures, applications in which throughput varies and where electrical costs are high. It takes advantage of technology perfected in the original two-stage EnergySmart system and applies it to a less-costly single-stage dryer configuration. The dryers can handle resin throughputs between 400 lbs/hr and 5000 lbs/hr (182 kg/hr and 2273 kg/hr). The Siemens-based control tends to be preferred in Europe and other international markets, while an Allen-Bradley platform is more often specified in North America. In either configuration, the same Conair technologies are used to slash energy waste and provide a higher degree of control over the drying process. In Optimizer™ Mode, the TouchView™ dryer control uses information gathered by a Conair Drying Monitor™ and regulates air temperature, dew point and air flow. Just enough heat energy is added to the bed of material in the drying hopper to maintain an optimum temperature profile. Too much air flow will result in wasted energy; too little air flow will result in poor drying performance. Once the proper conditions are established, they can be locked in with the touch of a finger. The controls maintain a stable temperature within the drying hopper regardless of throughput changes or variations in material temperature or ambient conditions.

Fast cost benefits Another innovative approach to material drying was presented by MORETTO S.p.A. through its EUREKA model. With the EUREKA project, MORETTO proposes not only an efficacious and reliable system, but it suplies also a financial tool able to guarantee a return of the investments with a sure date. The company's fully automatic high-volume modular drying systems, combine the new X MAX dryer and the FLOWMATIK controller with the new OTX hopper, enable a throughput of up to 8,000 kg/h capacity, in combination with a modular generator of 20,000 m

3/h - giving total flexibility of between three and 10 modular design dryer units and from 1 up to 32 drying hoppers, all without requiring either compressed air or cooling water. The result is faster, consistent and gentle drying of highly hygroscopic polymers - such as PET - with the benefit of a significant reduction in energy consumption. The factor separating this multi-tower system from conventional systems is the maintenance of a consistent, i.e. uniform, dew point throughout the process, the r eby r e a ching high efficiency levels and total operating flexibility, for example in the mix of preform sizes and weights. Efficiency is never compromised - even at lower throughputs.

The 'green-factor' labeled system with its extremely low energy consumption accommodates increasing throughputs of, for instance, PET preforms. This is particularly important as numbers of mould cavities are ever in-creasing. All the vital factors which influence the management and control of the drying process of numerous plastic granular materials - and PET in particular - are taken into consideration: type of material, granule size, bulk density, temperature, dew point, residence time, specific airflow, initial air moisture content, final residual moisture content in the granule, and viscosity. In a multi-dryer system, each unit, with its stand-alone air circuit and controlled by a dew po

Air Jordan XX9 29 Shoes More advanced auxiliary equipment are helping processors improve the efficiency of their production. New cooling/ drying equipment and blenders/mixers are responding to the market's demand for energy saving, efficiency and improved quality of finished products. Conair recently expanded its drying product line to include the new ES-1 single-stage desiccant drying system that offers advanced control and energy-saving features. The EnergySmart™ Single-Stage ES-1 system was developed for processors of PET and other polymers that require high drying temperatures, applications in which throughput varies and where electrical costs are high. It takes advantage of technology perfected in the original two-stage EnergySmart system and applies it to a less-costly single-stage dryer configuration. The dryers can handle resin throughputs between 400 lbs/hr and 5000 lbs/hr (182 kg/hr and 2273 kg/hr). The Siemens-based control tends to be preferred in Europe and other international markets, while an Allen-Bradley platform is more often specified in North America. In either configuration, the same Conair technologies are used to slash energy waste and provide a higher degree of control over the drying process. In Optimizer™ Mode, the TouchView™ dryer control uses information gathered by a Conair Drying Monitor™ and regulates air temperature, dew point and air flow. Just enough heat energy is added to the bed of material in the drying hopper to maintain an optimum temperature profile. Too much air flow will result in wasted energy; too little air flow will result in poor drying performance. Once the proper conditions are established, they can be locked in with the touch of a finger. The controls maintain a stable temperature within the drying hopper regardless of throughput changes or variations in material temperature or ambient conditions. Fast cost benefits Another innovative approach to material drying was presented by MORETTO S.p.A. through its EUREKA model. With the EUREKA project, MORETTO proposes not only an efficacious and reliable system, but it suplies also a financial tool able to guarantee a return of the investments with a sure date. The company's fully automatic high-volume modular drying systems, combine the new X MAX dryer and the FLOWMATIK controller with the new OTX hopper, enable a throughput of up to 8,000 kg/h capacity, in combination with a modular generator of 20,000 m3/h - giving total flexibility of between three and 10 modular design dryer units and from 1 up to 32 drying hoppers, all without requiring either compressed air or cooling water. The result is faster, consistent and gentle drying of highly hygroscopic polymers - such as PET - with the benefit of a significant reduction in energy consumption. The factor separating this multi-tower system from conventional systems is the maintenance of a consistent, i.e. uniform, dew point throughout the process, the r eby r e a ching high efficiency levels and total operating flexibility, for example in the mix of preform sizes and weights. Efficiency is never compromised - even at lower throughputs.

More advanced auxiliary equipment are helping processors improve the efficiency of their production. New cooling/ drying equipment and blenders/mixers are responding to the market's demand for energy saving, efficiency and improved quality of finished products. Conair recently expanded its drying product line to include the new ES-1 single-stage desiccant drying system that offers advanced control and energy-saving features. The EnergySmart™ Single-Stage ES-1 system was developed for processors of PET and other polymers that require high drying temperatures, applications in which throughput varies and where electrical costs are high. It takes advantage of technology perfected in the original two-stage EnergySmart system and applies it to a less-costly single-stage dryer configuration. The dryers can handle resin throughputs between 400 lbs/hr and 5000 lbs/hr (182 kg/hr and 2273 kg/hr). The Siemens-based control tends to be preferred in Europe and other international markets, while an Allen-Bradley platform is more often specified in North America. In either configuration, the same Conair technologies are used to slash energy waste and provide a higher degree of control over the drying process. In Optimizer™ Mode, the TouchView™ dryer control uses information gathered by a Conair Drying Monitor™ and regulates air temperature, dew point and air flow. Just enough heat energy is added to the bed of material in the drying hopper to maintain an optimum temperature profile. Too much air flow will result in wasted energy; too little air flow will result in poor drying performance. Once the proper conditions are established, they can be locked in with the touch of a finger. The controls maintain a stable temperature within the drying hopper regardless of throughput changes or variations in material temperature or ambient conditions. Fast cost benefits Another innovative approach to material drying was presented by MORETTO S.p.A. through its EUREKA model. With the EUREKA project, MORETTO proposes not only an efficacious and reliable system, but it suplies also a financial tool able to guarantee a return of the investments with a sure date. The company's fully automatic high-volume modular drying systems, combine the new X MAX dryer and the FLOWMATIK controller with the new OTX hopper, enable a throughput of up to 8,000 kg/h capacity, in combination with a modular generator of 20,000 m3/h - giving total flexibility of between three and 10 modular design dryer units and from 1 up to 32 drying hoppers, all without requiring either compressed air or cooling water. The result is faster, consistent and gentle drying of highly hygroscopic polymers - such as PET - with the benefit of a significant reduction in energy consumption. The factor separating this multi-tower system from conventional systems is the maintenance of a consistent, i.e. uniform, dew point throughout the process, the r eby r e a ching high efficiency levels and total operating flexibility, for example in the mix of preform sizes and weights. Efficiency is never compromised - even at lower throughputs.  The 'green-factor' labeled system with its extremely low energy consumption accommodates increasing throughputs of, for instance, PET preforms. This is particularly important as numbers of mould cavities are ever in-creasing. All the vital factors which influence the management and control of the drying process of numerous plastic granular materials - and PET in particular - are taken into consideration: type of material, granule size, bulk density, temperature, dew point, residence time, specific airflow, initial air moisture content, final residual moisture content in the granule, and viscosity. In a multi-dryer system, each unit, with its stand-alone air circuit and controlled by a dew poAir Jordan XX9 29 Shoes

The 'green-factor' labeled system with its extremely low energy consumption accommodates increasing throughputs of, for instance, PET preforms. This is particularly important as numbers of mould cavities are ever in-creasing. All the vital factors which influence the management and control of the drying process of numerous plastic granular materials - and PET in particular - are taken into consideration: type of material, granule size, bulk density, temperature, dew point, residence time, specific airflow, initial air moisture content, final residual moisture content in the granule, and viscosity. In a multi-dryer system, each unit, with its stand-alone air circuit and controlled by a dew poAir Jordan XX9 29 Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login