SYNERLINK offers a new innovative premium packaging solution for yogurts and desserts: the apsleever.

Designed for line integration, the apsleever shrink sleeves offer an adaptable system that reduces waste and product changeover time. The machine allows manufacturers to start production from undifferentiated packaging, which translates to storage and labor cost savings.

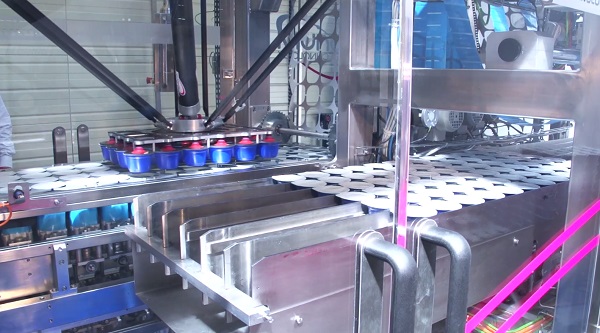

Robotic sleeve application system via the SynerLink apsleever

The apsleever, which has a smaller footprint than existing solutions at only 5 meters long, tracks cups from the filling process and synchronizes label changes with product changeover in real time. Its single, standard module can be added onto both FFS and FS lines to enable sleeve application on both packs and unit cups. Further, it can process several types of film, allowing producers to select preferred suppliers, whose product will be tested on the machine and validated by Aprium.

The apsleever can apply a sleeve label to all kinds of cup shapes without the need to turn the cup upside down. It can shrink the label in less than 3 seconds. These features make it ideal for delicate products such as yogurts and milk-based desserts, which should not be over-manipulated, turned upside down, or overheated.

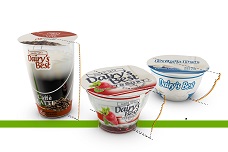

The SynerLink premium packaging solution will benefit yogurt and milk-based dessert producers, which need to ensure product quality and texture and a steady stream of new flavors to meet customers’ demands. The ability to mix flavors through multipacks will meet varying family members’ tastes and preferences toward delivering a more diversified customer experience. Moreover, the ability to offer products in a premium package that highlights a nice shape with a bright sleeve and perfectly positioned lid and deliver them in multipacks will help create new market opportunities.

The SynerLink premium packaging solution will benefit yogurt and milk-based dessert producers, which need to ensure product quality and texture and a steady stream of new flavors to meet customers’ demands. The ability to mix flavors through multipacks will meet varying family members’ tastes and preferences toward delivering a more diversified customer experience. Moreover, the ability to offer products in a premium package that highlights a nice shape with a bright sleeve and perfectly positioned lid and deliver them in multipacks will help create new market opportunities.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login